Orbital Fabrications had an eventful 2023, with several noteworthy developments and achievements. Here are some of the highlights:

Orbital Fabrications continued to focus on its in-house manufacturing capabilities, this has allowed us to provide our OEM customers a fully comprehensive service. We manufactured, tested and commissioned five Semiconductor MOCVD systems and provided services associated with a further ten MOCVD systems for future fitment.

Orbital Fabrications has established new and exciting partnerships within the Hydrogen industry, the scope of works is varied and can range from fully welded manifolds for high integrity purposes through to high pressure gas delivery panels. We are now undertaking an exciting project that will contain a multitude of welded applications in Inconel 625 for high temperature variations.

For pharmaceutical containment, we have seen a high demand for our stainless-steel manufactured containment solutions. Our skilled welders utilise their manual TIG welding experience to manufacture to the highest cleanliness standards.

We have maintained strong growth with our in-house manufacturing services enabling us to open a new business unit boasting further cleanroom space for manufacturing. We expect further growth in-line with our strategic OEM partners throughout 2024.

In Wales, Orbital completed an ultra-high purity (UHP) installation at Swansea University for the Centre of Integrative Semiconductor Materials (CISM), consisting of inert, flammable, toxic and pyrophoric gases. Orbital is also nearing completion of a tool hook-up package for the University of Cardiff at its Translational Research Hub (TRF), which uses similar gases across various applications.

Further North, in Macclesfield, Orbital completed a pharmaceutical project for Astra Zenica; repurposing an existing facility for an R&D application that if successful, would later be scaled for general production. This project involved stainless steel welded systems but also featured Hastelloy due to the corrosive nature of fluids involved.

Moving on to Manchester, Orbital is nearing completion on phase 2 of a brand new cleanroom at Nexperia’s production facility. Installing pipework systems for an array of tools supporting various applications within the semiconductor industry.

Orbital recently began work on the brand new KLA SPTS building in Newport. Orbital has been tasked with designing, manufacturing, installing, testing and commissioning the process pipework systems, inclusive of bespoke valve manifold boxes (VMB) and valve manifold panels (VMP).

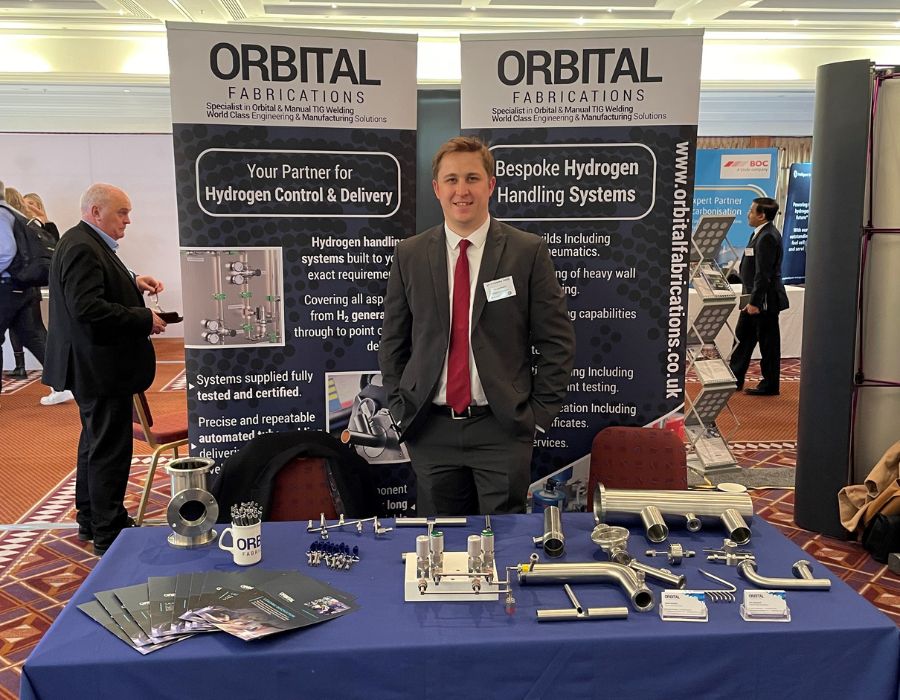

We detailed the UK’s net-zero goal investment into hydrogen fuel system infrastructure. We also exhibited at the Hydrogen and Fuel Cells Now Conference, where we demonstrated our latest developments and innovations in TIG welding for fabricating complex assemblies in stainless steel, utilising both automated orbital welding techniques alongside lathe and turntable TIG welding. It was the exhibition’s 19th year and is the largest and longest running hydrogen gathering in the UK.

Check out our Orbital Welding process here: https://www.youtube.com/watch?v=3VrbUDFrYow

Orbital Fabrications sponsored the Raptor Foundation Birds of Prey exhibit at the Bar Hill Fete & Festival. This amazing local charity offers 24-hour care and rehabilitation facilities for injured raptors. They provide a permanent, caring home for those birds that cannot be released back into the wild. As well as this, the Chairman of Orbital Fabrications, Ian Pearson, and his team competed in the 24-hour Citroen 2CV race, to raise money for Cancer Research. It was a tough yet exciting challenge for Ian and his team. They managed to raise £1,000 for Cancer Research and a further £500 for the brain tumour charity.

We at Orbital Fabrications would like to extend our heartfelt thanks to our customers and suppliers for their unwavering support throughout the year. Your trust in our services and products has been instrumental in our success, and we are grateful for the opportunity to work with you.

2023 has been a year of growth and innovation for us, and we couldn’t have done it without your support. We are proud to have been able to deliver high-quality solutions that meet your needs, and we look forward to continuing to do so in the future.

As we move forward into 2024, we remain committed to providing you with the best possible service and products. We will continue to innovate and improve our offerings, so that we can better serve your needs.

Once again, thank you for your support. We wish you all the best for the coming year.