Orbital Fabrications has the capability to manufacture Hydrogen control systems, associated pipework, or complete skid systems in our facility. We offer full turn-key solutions, assist with design and provide full documentation packages with traceability on materials, weld maps and test certificates. All of our welders are coded.

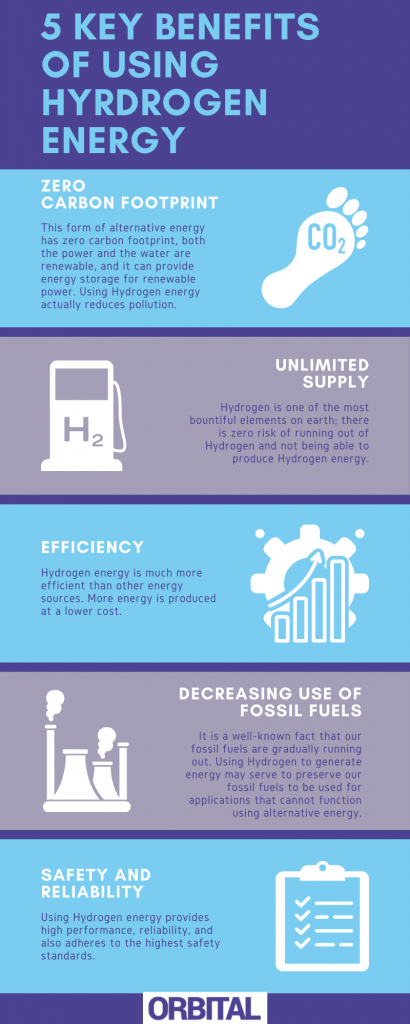

We have previously discussed how Hydrogen is used to generate energy; if you missed our article, take a look here https://www.orbitalfabrications.co.uk/hydrogen-the-alternative-energy-of-the-future/ Orbital is committed to working with Hydrogen energy for a number of reasons, below we discuss just some of the benefits of this highly efficient energy solution –

Find out more about how we use Hydrogen energy today:

https://www.orbitalfabrications.co.uk/hydrogen-the-alternative-energy-of-the-future/

Orbital Fabrications, based in Cambridge, is a market leader in orbital welding, specialist welding, and assembly of gas and fluid handling systems. Established in 1988, Orbital Fabrications offers specialised orbital welding and high-tech fabrication to a variety of clients within the Semiconductor, Pharmaceutical, Aerospace, Chemical and Allied industries.

Orbital Fabrications has more to offer than just welding. As well as computerised orbital welding, micro-TIG welding and manual welding, we also offer an assembly service both within our controlled workshop environment and within our cleanroom. Our state-of-the-art facilities also boast a CNC machining facility. All our services are supported by our testing and inspection procedures.

We specialise in the design and build of point of use gas cabinets, change-over panels, and electro-mechanical control units. We also fabricate high-quality vacuum exhaust systems and have developed equipment for exhaust gas filtration prior to its release into the atmosphere.