Hydrogen is the smallest element on the periodic table and interestingly, it is the most abundant chemical substance in the universe. Due to its extremely small molecular size, if there is even the slightest defect in a container or pipework filled with hydrogen, the hydrogen will find it and escape. In the case of hydrogen (and other high purity gases) process pipework applications, joints between sections of pipework naturally need to be very high quality and present the smallest number of potential leak paths possible, to mitigate the increased risk of leakage.

Additionally, when designing and installing high purity gas and fluid control systems and high-pressure hydrogen pipework, the pressure of the gas being carried by the pipework must not exceed the Maximum Allowable Working Pressure (MAWP) of the pipework itself. Therefore, all components of the process pipework, including any joints, must be manufactured and prepared to withstand the MAWP.

Comparison of Joint Mechanics

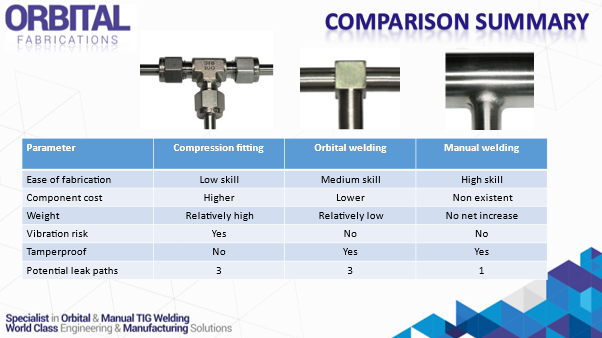

There are two main options when it comes to joining sections of process pipework: to either create a welded joint or use a compression fitting. Compression fittings can be used as a joining technique, but they must be fully leak tested and as mechanical fabrications they come with some inherent risks which may outweigh the comparative ease of their fabrication and installation. These fittings are comprised of a compression nut, a one or two ferules, and a coupling. They are relatively easy to fabricate, requiring only simple tooling and relatively low skill levels to complete. However, this type of fitting, although popular for its ease of use, has a comparatively high component cost, weight and is at risk of failure due to vibration. Furthermore, compression fittings by their nature are not tamperproof, and present a total of 3 potential leak paths (in the case of a tee fitting).

The Orbital Fabrications Solution

Creating a welded joint in between sections of hydrogen pipework is the second joining solution. Ultimately a welded solution is a single piece of stainless steel, as there are no other materials added to the construction.

The expert team at Orbital Fabrications offers two different techniques to the challenge of fabricating high quality, reliable process pipework. The first option, joining the sections through orbital welding, which has a medium level of ‘ease of fabrication’, as it requires specific automated welding equipment. The advantages are a relatively low component cost, a reduced weight and the risk of vibration is non-existent. Unlike a compression fitting, this welded joint is tamperproof.

Another option would be joining by ‘manual spur welding’. Manual spur welding is the most challenging fabrication process, requiring a skilled and qualified manual TIG welder to join the pipework. However, this method has a component cost of zero, and a practically no weight change as no additional material is being added to create the joint. The risk of vibration breaking the join is non-existent, and the joint itself is tamperproof. A manual spur welded joint is therefore, an extremely secure method of joining sections of process pipework. Crucially, a manual spur welded joint has only 1 potential leak path. Therefore, manual spur welded joints provide a greater level of security and integrity than a joint using a compression fitting.

About Orbital Fabrications

Orbital Fabrications has over 30 years’ experience in orbital welding services and is an industry expert in the design and installation of high purity gas and fluid control systems, high pressure hydrogen process pipework services, and orbital tube welding. Our experienced team of high purity welding experts can weld tubing to fabricate components for the hydrogen, semiconductor, aerospace, pharmaceutical, chemical, and oil & specialist gases industries. Our engineering know-how and advanced manufacturing capabilities allow us to meet the ever-changing demands of the sectors we supply. Whether it’s a full turnkey project solution, or a one-off fabrication, Orbital can assist. The specialist team at Orbital Fabrications offers the very best in welded joints in high purity gas and fluid control systems, including tee fitting manual welds, meaning that you can be assured that your process pipework has the least possible potential leak paths. Orbital’s team of manual TIG welders can weld a range from micro TIG assemblies though to 6” bore valve stubs and is accredited to the BS EN ISO 15614-1:2004+A2:2012, and ASME-IX welding standards.

To learn more about Orbital’s capabilities, contact us today.